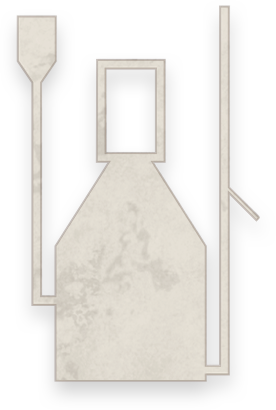

Heat source

A hot plate heats the water and converts it into steam. At Young Living distilleries, the correct temperature of the steam is crucial, and the degree of heat is determined by the plant being distilled. Gas heaters warm the water, which is stored in massive holding tanks.